9.6x5mm 5v active circuit magnetic type buzzer

Basic Info

Model No.: MB9650+2705PA

Product Description

Customer: | Part No: | |||||

Product: Magnetic Buzzers | SWT Part No: MB9650+2705PA | |||||

Technical Terms | ||||||

Rated Voltage (VDC) | 5 | |||||

Operating Voltage (VDC) | 4~7 | |||||

Max.Current Consumption (mA) | 30 | |||||

Min. Sound Output at 10cm(dB) | 80 | |||||

Resonant Frequency (HZ) | 2700±300 | |||||

Operating Temperature (°C) | -25 +80 | |||||

Storage Temperature (°C) | -30 +85 | |||||

Housing Material | PPO | |||||

Weight (g) | 0.5 | |||||

| Buzzer Soldering process | Soldering Parameter | |||||

Temp.( °C) | Time(Sec.) | Times | ||||

Lead Free |

| Reflow soldering | 245±15 | above 180°C time 40~70 | 3 | |

| Wave soldering | 260±5 | 4~8 | 2~3 | ||

| Manual soldering | 350±10 | 1~3 | 2~3 | ||

Sample Test Report Sample Description Type Customer Sample Qty. Test Qty.

Sample Test Report Sample Description Type Customer Sample Qty. Test Qty. 10pcs | 10pcs |

Result

Result Pass( √ ) | Fail( ) |

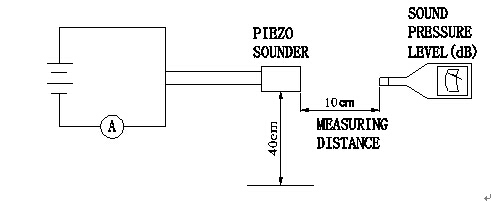

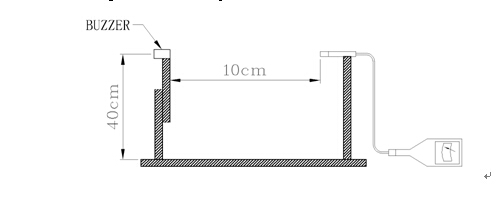

In the measuring test, buzzer is placed as follows:

In the measuring test, buzzer is placed as follows:  2. Typical Frequency Response Curve

2. Typical Frequency Response Curve  3. RELIABILITY TEST

3. RELIABILITY TEST NO. | ITEM | TEST CONDITION AND REQUIREMENT | |||||||||||||||||||||

1 | High Temperature Test (Storage) | After being placed in a chamber with 80ï2ºC for 96 hours and then being placed in normal condition for 2 hours. Allowable variation of SPL after test: ï10dB. | |||||||||||||||||||||

2 | Low Temperature Test (Storage) | After being Placed in a chamber with -30ï2ºC for 96 hours and then being placed in normal condition for 2 hours. Allowable variation of SPL after test: ï10dB. | |||||||||||||||||||||

3 | Humidity Test | After being Placed in a chamber with 90-95% R.H. at 40ï2ºC for 96 hours and then being placed in normal condition for 2 hours. Allowable variation of SPL after test: ï10dB. | |||||||||||||||||||||

4 | Temperature Cycle Test |  . 5 Drop Test Drop on a hard wood board of 4cm thick, any directions ,6 times, at the height of 75cm . Allowable variation of SPL after test: ï10dB. 6 Vibration Test After being applied vibration of amplitude of 1.5mmwith 10 to 55 Hz band of vibration frequency to each of 3 perpendicular directions for 2 hours . Allowable variation of SPL after test: ï10dB. 7 Solderability Test Lead terminals are immersed in rosin for 5 seconds and then immersed in solder bath of +300ï5ºC for 3ï1 seconds . 90% min. lead terminals shall be wet with solder (Except the edge of terminals). 8 Terminal Strength Pulling Test The force of 9.8N(1.0kg) is applied to each terminal in axial direction for 10 seconds. No visible damage and cutting off. 4,Package . 5 Drop Test Drop on a hard wood board of 4cm thick, any directions ,6 times, at the height of 75cm . Allowable variation of SPL after test: ï10dB. 6 Vibration Test After being applied vibration of amplitude of 1.5mmwith 10 to 55 Hz band of vibration frequency to each of 3 perpendicular directions for 2 hours . Allowable variation of SPL after test: ï10dB. 7 Solderability Test Lead terminals are immersed in rosin for 5 seconds and then immersed in solder bath of +300ï5ºC for 3ï1 seconds . 90% min. lead terminals shall be wet with solder (Except the edge of terminals). 8 Terminal Strength Pulling Test The force of 9.8N(1.0kg) is applied to each terminal in axial direction for 10 seconds. No visible damage and cutting off. 4,Package

More Application Contact us if you need more details on Buzzer. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Buzzer、Buzzer. If these products fail to match your need, please contact us and we would like to provide relevant information. More Application Contact us if you need more details on Buzzer. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Buzzer、Buzzer. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Magnetic Buzzer > Self drive type Premium Related Products Other Products

Hot Products 38mm 25kHz Piezo Type Waterproof Ultrasonic SpeakerHumidifier Spray Face Special Micro Atomization Piece with PCBguangdong factory alarm piezo ceramic disc 3.0khz 35mm piezo diaphragmpiezo type wireless buzzer smd buzzer 12x12mm 5v smd buzzer piezowholesale piezo ceramic element round 5khz 21mm piezo electric ceramics12*12mm side opening smd piezo buzzer 5v buzzer12mm 5v active type dc buzzer car alarm beeperbest seller piezoelectric buzzer element 31mm stainless steel discs12mm 9khz brass piezo ceramic element with wires micro piezodia. 57mm micro speaker 0.5w 1w 8ohm piezo tweeter40khz waterproof ultrasound transducer / 18mm transducerpiezo atomizer circularity 16mm 1700KHz ultrasonic atomizer partpiezo ceramic ultrasonic transducer part elementmagnetic buzzer size 12*8.5mm 5V musical magnetic buzzerSMD magnetic buzzer manufacture 8.5*8.5.3mm 2.7KHz wholesale magnetic buzzerLound sound DC piezo buzzer with diameter 22mm 12v active piezo buzzer |