28KHZ 50W 60W 100W 120W Korea Dishwasher Semiconductor Ultrasonic Transducer For Ultrasonic Cleaner

Product Description

28KHZ 50W 60W 100W 120W Korea Dishwasher Semiconductor Ultrasonic Transducer For Ultrasonic Cleaner

![]()

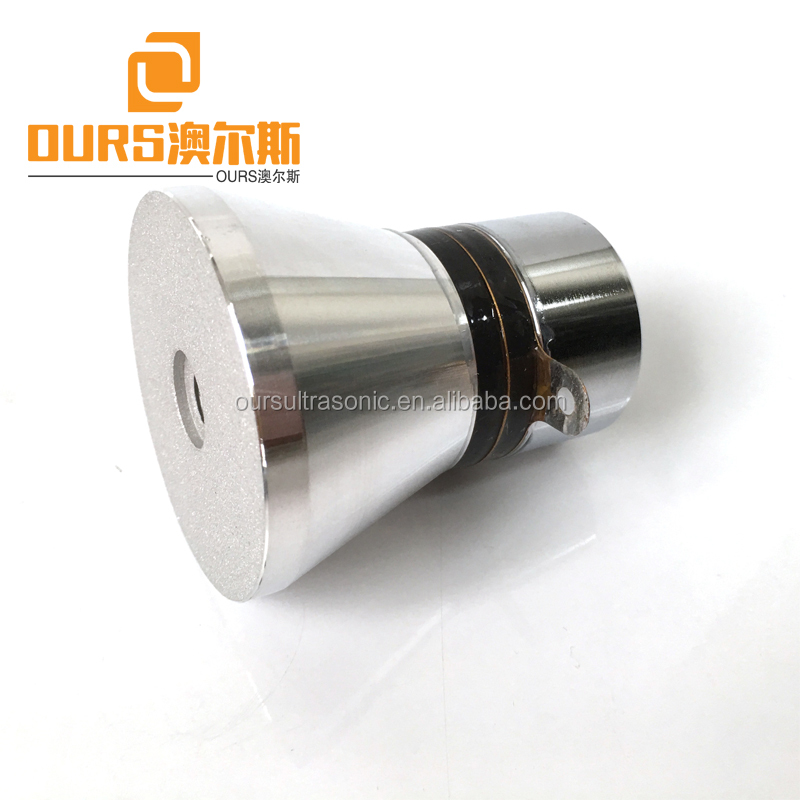

Ultrasonic vibrator, also called ultrasonic vibrating head, ultrasonic vibrating head, is a kind of ultrasonic transducer and the core component of Ultrasonic cleaning machine. We call the whole of ultrasonic transducer and horn connected as vibrator. Ultrasonic transducer is one of the important components in the ultrasonic cleaning machine and ultrasonic vibration plate, which largely determines the quality of the ultrasonic effect.

Our company provides professional ultrasonic transducers with stable quality, high efficiency output and moderate price based on many years of ultrasonic cleaning experience, combined with the opinions and feedback of the majority of users.

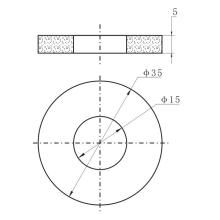

Ultrasonic transducer is a device that converts high-frequency electric energy into mechanical vibration. The high-frequency electric energy input by the ultrasonic generator is matched with the Piezoelectric Ceramic sheet of the resonance frequency of the ultrasonic transducer. The electric energy is converted by the piezoelectric effect of the material Converted into mechanical vibration, that is, ultrasonic vibration, is transmitted to the water medium through the ultrasonic transducer, forming negative pressure bubbles and shock waves in the water, and transmitting them in the tax-based solution to achieve the effect of cleaning the surface stains of the workpiece. The transducer is mainly composed of aluminum block, piezoelectric ceramic sheet and insulating layer.

Ultrasonic transducer application:

1. Among all cleaning methods, ultrasonic cleaning is the most efficient and effective one. The reason why ultrasonic cleaning can achieve such an effect is closely related to its unique working principle and cleaning method.

2. We know that in production and life, there are many things that need to be cleaned, and there are many types and links that need to be cleaned, such as: removing pollutants from objects, dredging small holes, and common manual cleaning methods for special-shaped objects and hidden parts of objects. It is undoubtedly unable to meet the requirements. Even steam cleaning and high-pressure water jet cleaning cannot meet the higher cleanliness requirements. Ultrasonic cleaning can also kill bacteria, dissolve organic pollutants, and prevent over-corrosion. Therefore, ultrasonic cleaning Is increasingly widely used in all walks of life:

(1) Machinery industry: removal of anti-rust grease; cleaning of measuring tools; degreasing and derusting of mechanical parts; cleaning of engines, carburetors and auto parts; dredging and cleaning of filters and screens, etc.

(2) Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removing carbon deposits; removing oxide scale; removing polishing paste; surface activation treatment of metal workpieces, etc.

(3) Instrument and meter industry: high cleanliness of precision parts, cleaning before assembly, etc.

(4) Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleaning of mechanical and electronic parts such as high voltage contacts.

(5) Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of laboratory utensils, etc.

(6) Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

(7) Clocks and watches, decoration industry: remove sludge, dust, oxide layer, polishing paste, etc.

(8) Chemical and biological industries: cleaning and descaling of laboratory utensils.

(9) Optical industry: degreasing, sweating and dust removal of optical devices.

(10) Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

(11) Petrochemical industry: cleaning and dredging of metal filter screens, cleaning of chemical containers, exchangers, etc.

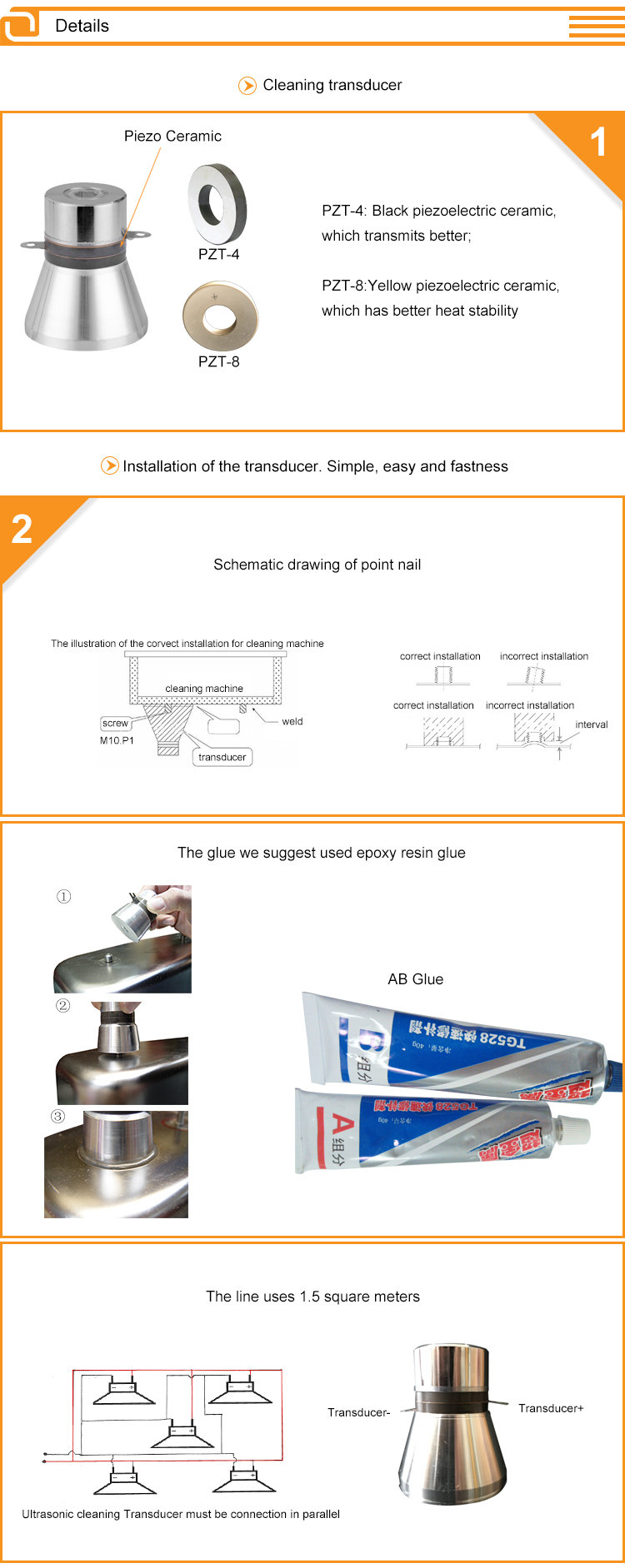

Ultrasonic vibrator installation process:

1. Preparation tools: Argon arc welding, No. 10 hexagon wrench, chromium iron tin wire, 2.5 square high temperature wire, 2*2.5 cable wire, vibrator glue, (wire stripper, casing, cable tie, sandblasting machine, Pipe fittings, etc.).

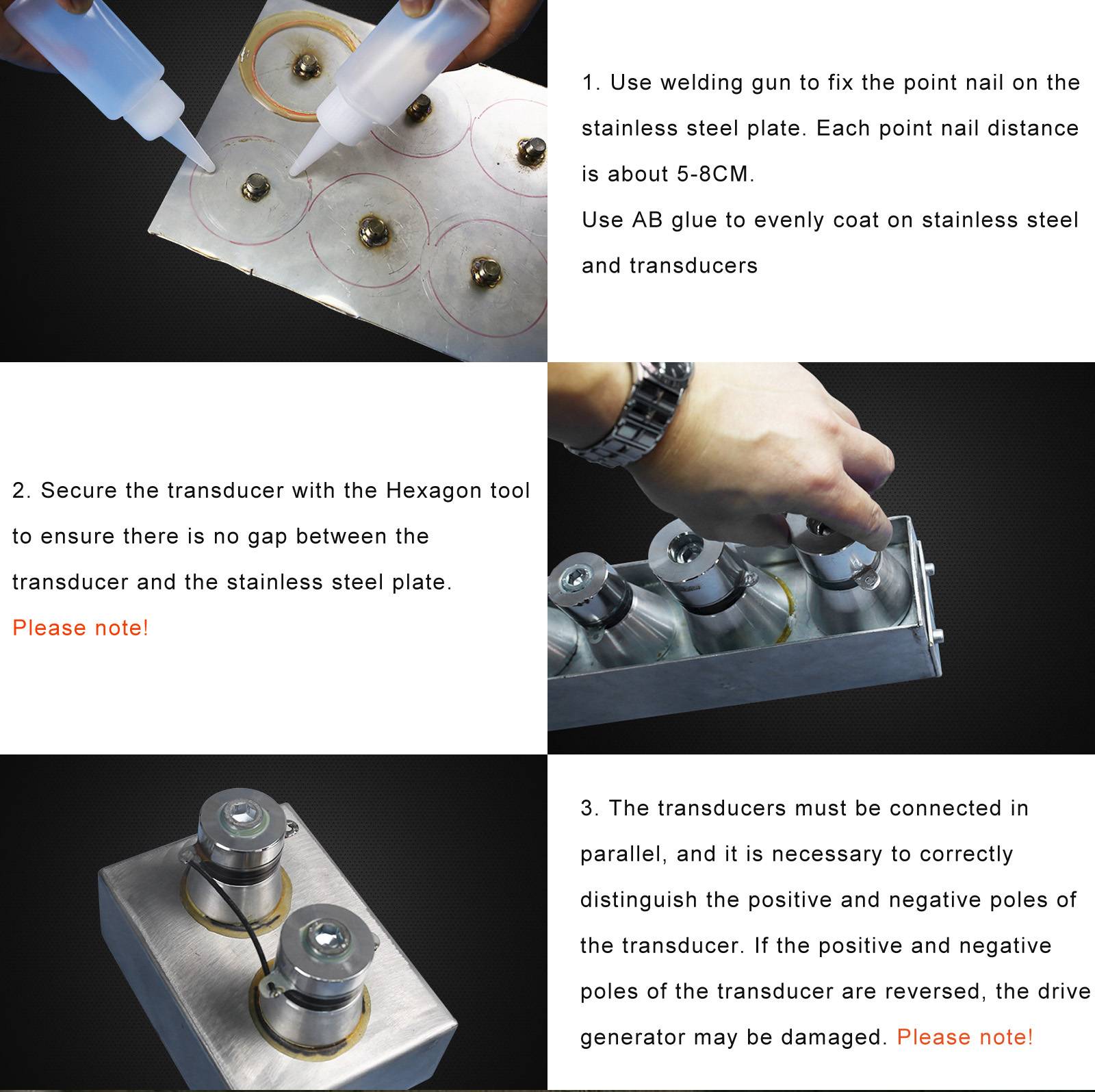

2. Welding screws: Calculate the arrangement of the vibrator, weld the screws at the cleaned position, and then clean the surrounding of the screw, make sure it is level, so as not to affect the installation of the vibrator.

3. Glue configuration: Squeeze the A glue around the screw, then squeeze the B glue next to the A glue, and then quickly stir the AB glue with a small iron rod to make it fully mixed.

4. Install the vibrator: twist the transducer a little harder to squeeze out the air and excess glue between the bottom and the contact surface of the cylinder bottom, so that the vibrator is more tightly combined with the stainless steel as a whole.

5. Curing and condensing: curing at a relatively high room temperature, wiring can be done in 4-8 hours, and the machine can be powered on after 24 hours.

Note: 1. A metal nail machine can also replace argon arc welding.

2. The welding screws must be fully welded, otherwise they will fall off easily.

3. Regarding curing, temperature should be considered for the length of time. If the temperature is low, the time will be longer, and if the temperature is high, it will be faster. It is recommended to operate at room temperature. Do not overheat even if it is heated. Appropriate is best.

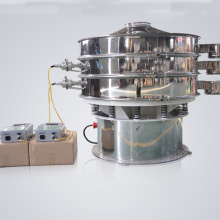

The principle of ultrasonic vibrator arrangement:

(1) Different product layouts have different requirements for cleaning, such as the degree of oil contamination of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of the cleaning process, all require targeted selection.

(2) The arrangement of vibrators is not the more dense the better, the best is the right one.

![]()

![]()

28KHZ 50W 60W 100W 120W Korea Dishwasher Semiconductor Ultrasonic Transducer For Ultrasonic Cleaner

Product Categories : Ultrasonic Cleaning Transducer

Premium Related Products