Manufacture 40kHz Immersible Ultrasonic Cleaner Transducer For Cleaning Locomotive Parts

Product Description

Manufacture 40kHz Immersible Ultrasonic Cleaner Transducer For Cleaning Locomotive Parts

![]()

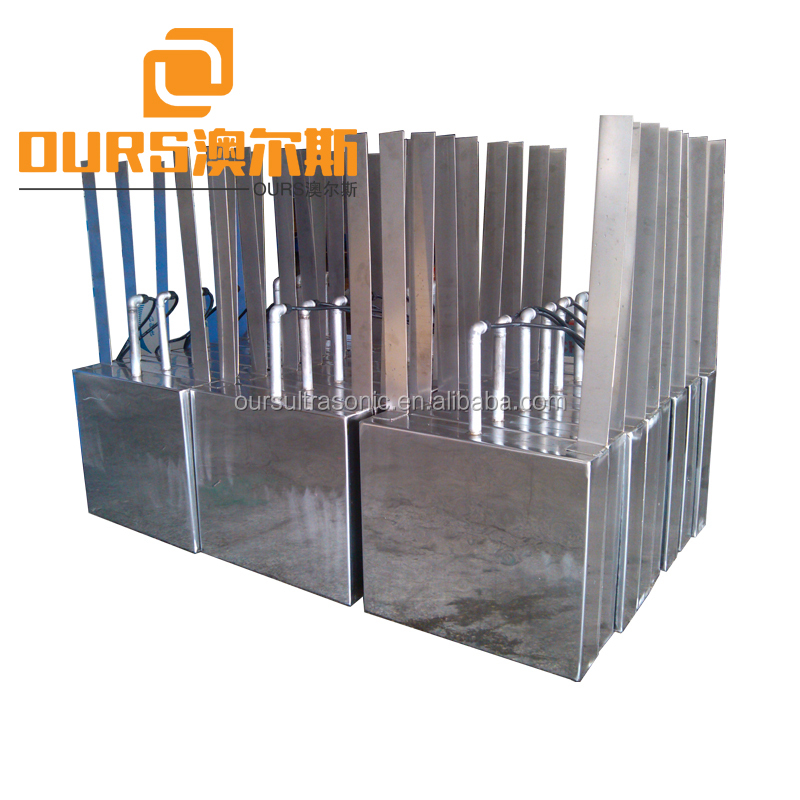

Ultrasonic immersible transducer pack also called the inputting type ultrasonic vibration plates, The input type ultrasonic shock plate device consists of shock plate and ultrasonic generator. When the trough type ultrasonic cleaner is not suitable for a specific working environment, the input type shock plate device can be used. For example, in the existing equipment, there is a common cleaning tank, you can add shock plate device, refitted into an Ultrasonic cleaning machine. All stainless steel structure, acid and alkali resistance, beautiful and durable. The split structure is adopted, and the high frequency connection with socket between the shock plate and the ultrasonic generator is adopted, which is convenient to use and maintain. The installation and layout are flexible, and can be made into three types: bottom shock type, side shock type and top shock type according to different needs to meet various cleaning requirements.

Scope of application: cleaning electroplated parts before plating, clocks and watches, hardware and machinery parts, polyester filter core, semiconductor silicon, tools, lenses, spectacle frames, jewelry, glassware

The application principle of the ultrasonic vibration plate is that the high-frequency oscillation signal sent by the ultrasonic generator is converted into high-frequency mechanical oscillation by the transducer and transmitted to the medium. The ultrasonic wave in the cleaning solvent radiates forward in the dense and dense phases in the cleaning liquid, so that The flow of liquid produces tens of thousands of tiny bubbles. The tiny bubbles (cavitation nuclei) in the liquid vibrate under the action of the sound field. When the sound pressure reaches a certain value, the bubbles grow rapidly, then suddenly close, and the bubbles close When a shock wave is generated, thousands of atmospheric pressures are generated around it, destroying insoluble dirt and dispersing them in the cleaning fluid. When the group particles are wrapped in oil and adhere to the surface of the cleaning part, the oil is emulsified and the solid particles are Separation, so as to achieve the purpose of cleaning the surface of the cleaning part.

The ultrasonic vibration plate can be designed in different positions in the cleaning tank according to the needs of customers;

The cleaning tank adopts stainless steel structure, acid and alkali resistance, and durable;

Different specifications can be combined and spliced to meet various cleaning needs.

Scope of application:

The matching original sink becomes a sink with ultrasonic cleaning function, which is widely used in optics, photovoltaic and electroplating industries.

The vibration plate is divided into: input ultrasonic vibration plate, flange type vibration plate and detachable ultrasonic vibration plate. The split structure is adopted, and the high-frequency wire with socket is used for connection between the vibration plate and the ultrasonic generator, which is convenient for use and maintenance.

1. Use high-strength imported glue and fix the Ultrasonic Transducer with welding screw to prevent leakage and dampness.

2. Vibrating plate is made of high-quality imported SUS316 2.5mm stainless steel plate. Vibrating surface is made of SUS316L.2.5mm stainless steel with hard chromium plating. Power connection line is protected by SUS304*2M stainless steel soft nozzle. Titanium alloys are used for strong acidic liquid solvents. Overall acid and alkali resistance, beautiful and durable.

3. Using advanced welding technology, laser welding, professional Japanese technicians welding vibration plate

4. One set of free spare parts can be purchased for 30 sets of products of the same specifications at a time.

5. Vibrating plate has no heat, no leakage, low noise, no whistle and low power attenuation.

6. A complete set of schemes can be made according to the specific conditions of customers.

7. Explosion-proof flakes, explosion-proof design, special sensors installed in the vibration plate can detect the changes in the internal environment of the vibration plate and timely feedback to the generator to avoid accidents.

8. Under proper operating conditions, non-man-made damage can be replaced within one year, and the oscillator will not attenuate within two years.

Type Description

A.Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B.Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C.Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D.Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E.Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F.Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G.Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H. Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X.Non-standard mounting

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

| ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

| ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

| ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

| ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

| ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

| ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

| ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

| ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

| ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

| Above are single frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

![]()

Manufacture 40kHz Immersible Ultrasonic Cleaner Transducer For Cleaning Locomotive Parts

Product Categories : Ultrasonic equipment > Ultrasonic immersible transducer pack