90KHZ High frequency Submersible Ultrasonic Cleaner For Oil Cooler Degreasing

Product Description

90KHZ High frequency Submersible Ultrasonic Cleaner For Oil Cooler Degreasing

![]()

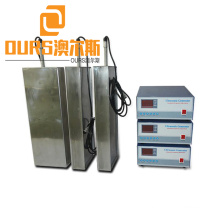

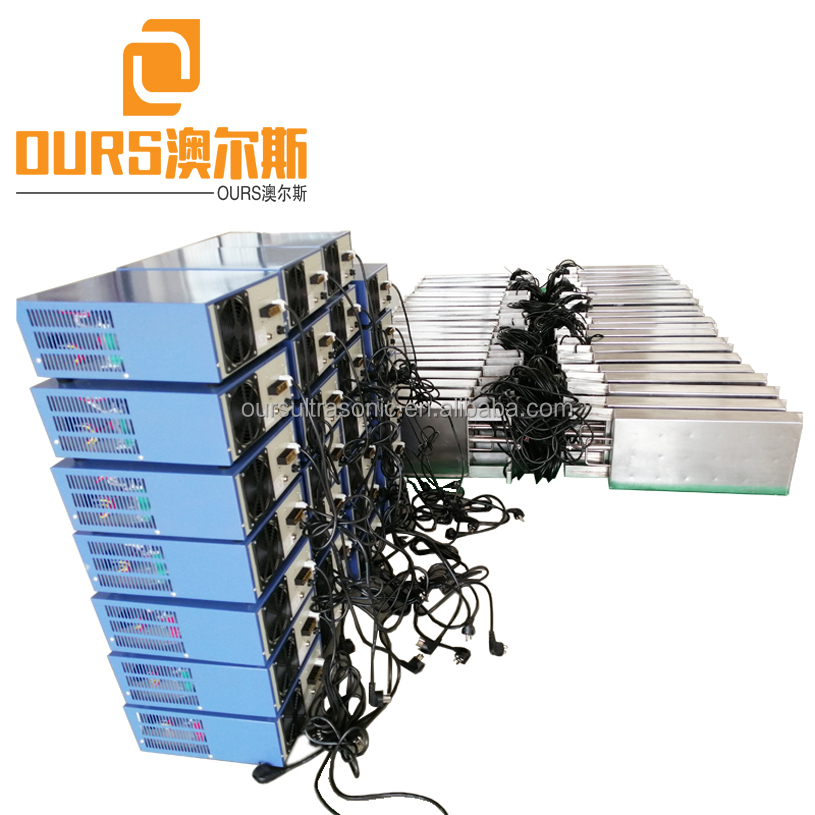

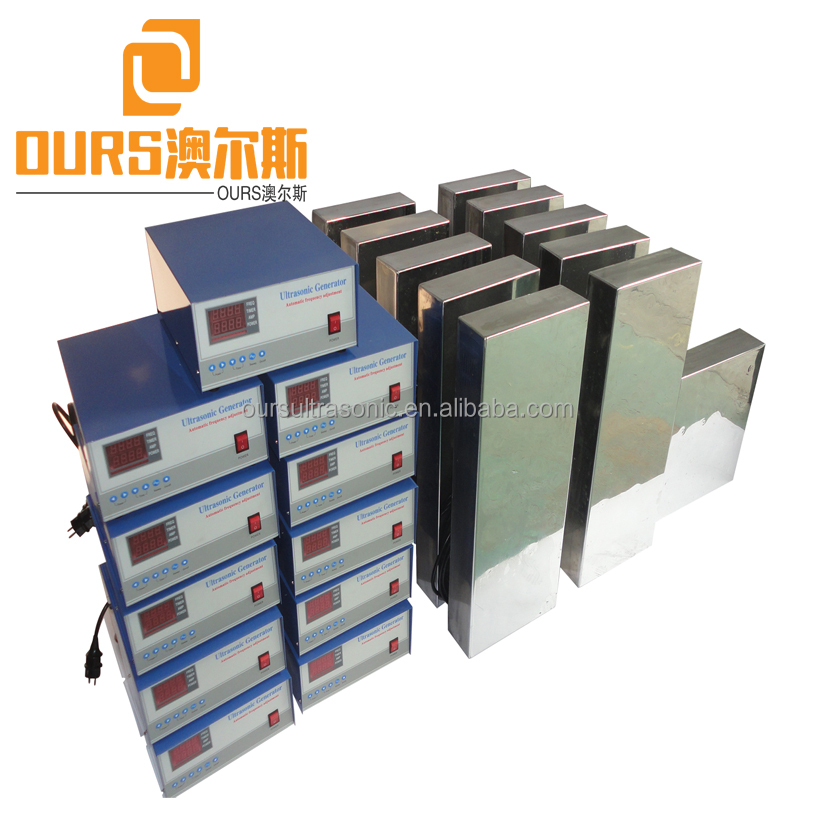

High-frequency Submersible Ultrasonic Transducer is composed by high frequency high frequency ultrasonic generator, high frequency ultrasonic transducer, stainless steel tanks etc.. In order to break decades of Ultrasonic equipment of single frequency and can not meet the purpose of production testing, our company special independent research and development of the ultrasonic stability, high Q value, high efficiency of two, three, four kinds of arbitrary frequency conversion multi frequency ultrasonic cleaner. Through two, three, four kinds of frequency free conversion, ultrasonic low, medium and high frequency in the same equipment in the free conversion of the working mode, so as to achieve the purpose of the production process.

The ultrasonic generator adopts the current internationally leading externally excited oscillation circuit structure, which increases the output power by more than 15% compared with the traditional self-excited oscillation circuit structure, which can maximize the potential of the transducer. Working voltage AC220±10V. It has protection measures such as overvoltage, overcurrent and output short circuit. It has the functions of frequency fine-tuning and frequency automatic tracking, which can achieve the best effect under different working conditions. The cleaning liquid is driven to form a fine backflow, so that the dirt on the workpiece is quickly removed from the surface of the workpiece while being ultrasonically peeled, and the cleaning efficiency is improved. With the function of stepless power adjustment, the output power can be adjusted continuously from 10% to 100% to meet the requirements of various cleaning objects. The ultrasonic power is adjustable from 0 to 100%.

Features:

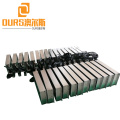

Material: The vibration plate is made of imported SUS304 2.5mm stainless steel plate, and the vibration surface is made of SUS316 2.5mm stainless steel plate.

1. Surface: Ultrasonic vibration surface is electroplated with hard chrome 5um to enhance the service life of the vibration surface.

2. Structure: The whole machine is equipped with a movable hook device for easy installation or movement. It uses special imported glue and welding screws to fix the ultrasonic transducer and is durable. The frequency is 25KHZ/28KHZ/40KHZ and Other frequencies are optional. The whole machine is all stainless steel structure.

3. Electrical system: all electrical components are made of imported high-quality parts, to achieve zero failure, and reduce unnecessary troubles caused by professional on-site maintenance due to failures during use.

4. Ultrasonic generator: adopts the digital frequency synthesis technology under the control of microcomputer, the ultrasonic power is continuously adjustable (digital display), and has perfect protection functions: overheating, overcurrent protection, and a four-bit timer to make time control precise To seconds. It also has a frequency sweep function.

4. Power supply: heating: 220V/50HZ

5. Scope of application: cleaning of hardware, electronics, clocks, machinery, tools, glasses, jewelry, semiconductor silicon wafers, polyester spinnerets, polyester filters, and glassware.

Board material: SUS304/316 T=2.5mm

Ultrasonic vibration plate size: size can be customized according to customer needs

1. Use high-strength imported glue and fix the ultrasonic transducer with welding screw to prevent leakage and dampness.

2. Vibrating plate is made of high-quality imported SUS316 2.5mm stainless steel plate. Vibrating surface is made of SUS316L.2.5mm stainless steel with hard chromium plating. Power connection line is protected by SUS304*2M stainless steel soft nozzle. Titanium alloys are used for strong acidic liquid solvents. Overall acid and alkali resistance, beautiful and durable.

3. Using advanced welding technology, laser welding, professional Japanese technicians welding vibration plate

4. One set of free spare parts can be purchased for 30 sets of products of the same specifications at a time.

5. Vibrating plate has no heat, no leakage, low noise, no whistle and low power attenuation.

6. A complete set of schemes can be made according to the specific conditions of customers.

7. Explosion-proof flakes, explosion-proof design, special sensors installed in the vibration plate can detect the changes in the internal environment of the vibration plate and timely feedback to the generator to avoid accidents.

8. Under proper operating conditions, non-man-made damage can be replaced within one year, and the oscillator will not attenuate within two years.

The input type ultrasonic shock plate device consists of shock plate and ultrasonic generator. When the trough type ultrasonic cleaner is not suitable for a specific working environment, the input type shock plate device can be used. For example, in the existing equipment, there is a common cleaning tank, you can add shock plate device, refitted into an Ultrasonic cleaning machine. All stainless steel structure, acid and alkali resistance, beautiful and durable. The split structure is adopted, and the high frequency connection with socket between the shock plate and the ultrasonic generator is adopted, which is convenient to use and maintain. The installation and layout are flexible, and can be made into three types: bottom shock type, side shock type and top shock type according to different needs to meet various cleaning requirements.

Scope of application: cleaning electroplated parts before plating, clocks and watches, hardware and machinery parts, polyester filter core, semiconductor silicon, tools, lenses, spectacle frames, jewelry, glassware

Applied areas of electroplating industry: grease, polishing wax and dirt removal.

Pharmaceutical industry: Chinese medicine extraction, bottle cleaning. Optical industry: lens, prism, lens, frame, liquid crystal glass, etc. before and after coating or assembly cleaning.

Machinery industry: oil pump nozzle, engine parts, steam and friction parts, compressor parts, sewing machine parts, metal stamping parts cleaning.

Hardware industry: hardware tools, garden tools, medical equipment cleaning. Other industries: ceramics, tableware, lamps, accessories, crystal, metal pipe cleaning. This product is made of imported high quality stainless steel. The radiant surface of vibration plate has been specially treated, and its service life has been prolonged by more than 50%. It is easy to install, and can be installed at the bottom of the groove to radiate the ultrasonic wave upward, or on the side of the groove or on the liquid surface to emit the ultrasonic wave downward. The specific installation method should be determined according to the shape of the workpiece and the cleaning requirements. The ultrasonic power and the size of the vibration box should be determined according to the volume of the cleaning tank. The general power density should be between 8 and 15KW/m.

Machinery and equipment cleaning advantages:

Good cleaning effect, high cleanliness and uniform cleanliness of all workpieces

_Cleaning speed is fast and production efficiency is improved

_No need to touch the cleaning fluid by hand, and clean the deep holes, slits and hidden parts safely and reliably.

_No damage to workpiece surface

_Save solvents, heat, workplaces and manpower, etc.

Type Description

A.Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B.Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C.Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D.Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E.Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F.Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G.Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H. Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X.Non-standard mounting

| Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

| ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,120.130 | 300 | 6 |

| ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,120.130 | 600 | 12 |

| ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,120.130 | 1000 | 20 |

| ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,120.130 | 1200 | 24 |

| ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,120.130 | 1500 | 30 |

| ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,120.130 | 1800 | 36 |

| ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,120.130 | 2000 | 40 |

| ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,120.130 | 2400 | 48 |

| ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,120.130 | 3000 | 60 |

| ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,120.130 | 5000 | 100 |

| Above are single frequency Ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

![]()

90KHZ High frequency Submersible Ultrasonic Cleaner For Oil Cooler Degreasing

Product Categories : Ultrasonic equipment > Ultrasonic immersible transducer pack